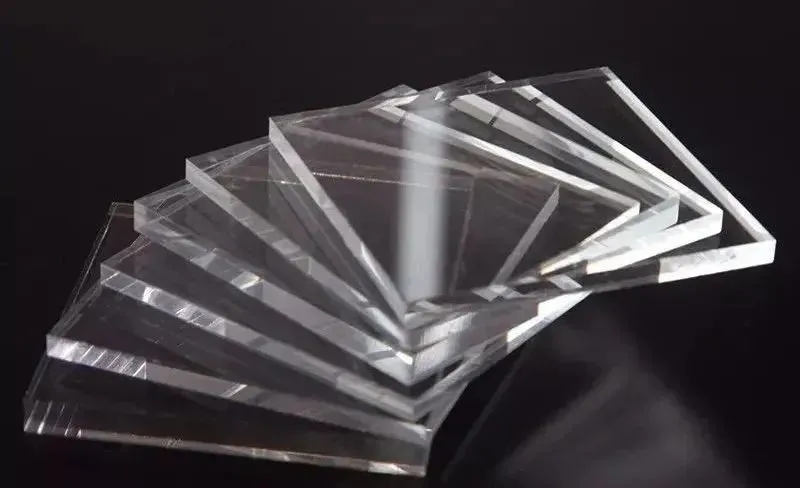

Acrylic is an organic compound, has good light transmission, its transparency and light transmission like glass, light transmission rate of more than 92%, the advantage lies in sun protection and waterproof, long-time use in the outdoor is not afraid of material deterioration, anti-aging performance is good.

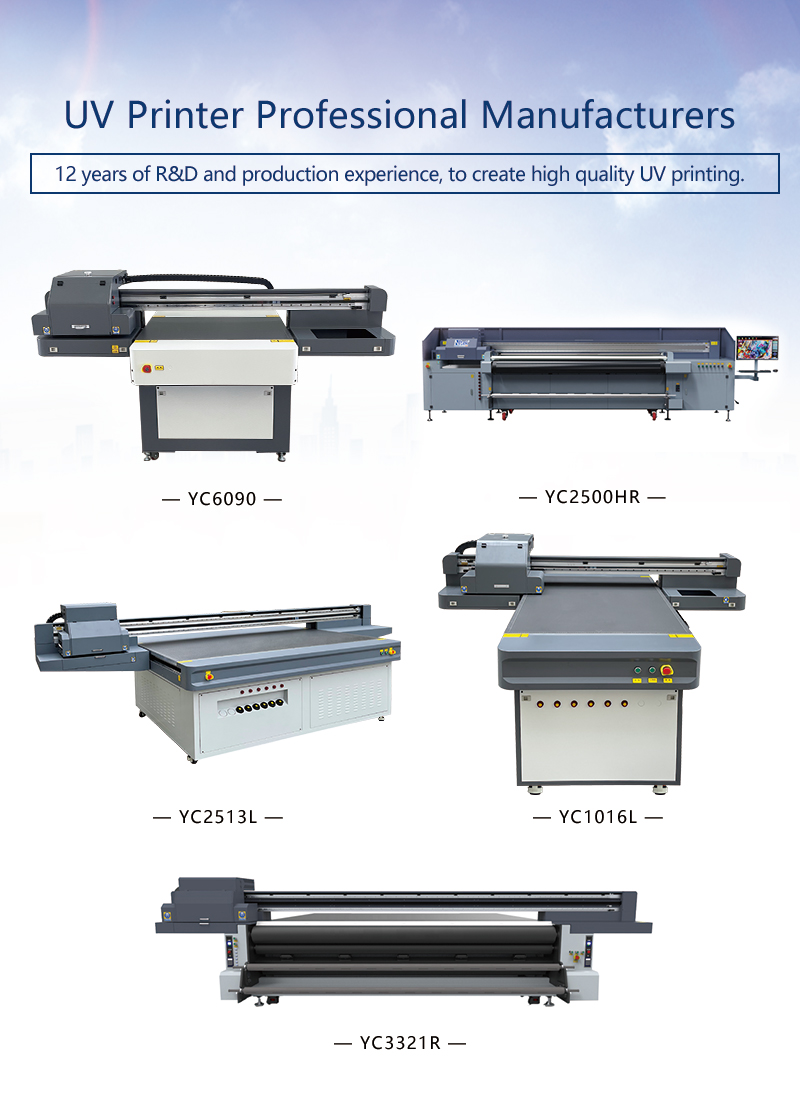

Acrylic UV printing skills

Acrylic is often made into logo signs, corporate culture display boards and so on. Acrylic is a very good flat material, printed on top of acr, can print out the bump sense, hand touch layered, more visual effects.

What are the problems that need to be paid attention to when UV printing acrylic sheets?

● When the UV printer is running, do not turn off the UV printer or unplug the power.UV printing belongs to digital printing, which is controlled by computer. If the power is turned off, the printing will be interrupted.

● Acrylic surface is smooth, if there is dust in the air of UV printing environment, it is easy to accumulate on the surface of the material, causing the pattern to expose white and omit other colors.

●UV printing, spray head and acrylic height should be suitable, spray head from acrylic too high or too low will cause printing image blur or double.

● acrylic UV printing before spraying coating on the printing surface, because the surface of acrylic is relatively smooth, directly above the UV printing image is easy to scrape, spray coating can make UV pigment better attached to it is not easy to scrape off.

How to remove screen printing error

With the wide use of acrylic materials, many customers are also more and more like acrylic color printing products, coupled with the combination of exquisite high-definition UV process, can be said to be the icing on the cake.So we know when acrylic UV printing, the picture is sprayed wrong or the effect is not ideal, what should be done?

Here we share the method of removing printing errors of acrylic screen:

● if it is just printing found unhappy, can spray on alcohol, after a while gently wipe can erase;

● More than 12 hours can be soaked in alcohol for 30 minutes can be torn off (can also use warm water soak, the time is relatively long);

● If it is more than 24 hours, you can use hydrogen peroxide, banana water cleaning.

Acrylic storage method

Acrylic is widely used, but in the process of transportation and storage, we should pay attention to the following:

1, acrylic plate can not be stored in one place with other organic solvents, but not in contact with organic solvents.

2. In the process of transportation, the surface protective film or protective paper shall not be chafed.(because of the high permeability of acrylic itself, easy to produce scratches, and more friction with the outside world, scratches will be more obvious).

3, can not be used in the temperature over 85℃ environment.(Acrylic is easy to become soft in high temperature)

4, daily cleaning, with a wet towel or newspaper wipe can be, such as smudges can be dipped in a towel beer or warm vinegar wipe, in addition to the current market can also be used to sell the glass cleaning agent, avoid with strong acid and alkaline solution clean.The surface of winter yakeli products is easy frost, can dip in with cloth thick brine or liquor will wipe, the effect is very good.

5, acrylic plate cold and hot expansion coefficient is very large, due to the temperature change should be considered to reserve expansion gap.